The Role of AI in Optimizing Supply Chain Operations

Chosen theme: The Role of AI in Optimizing Supply Chain Operations. Discover how predictive intelligence, automation, and human-centered design unify planning, inventory, logistics, and sustainability to build resilient, transparent, and efficient networks. Join the conversation, subscribe for fresh insights, and share your toughest supply chain challenge.

From Forecast to Fulfillment: AI-Powered Demand Planning

Beyond single-point predictions, AI models generate probability distributions that reflect uncertainty and seasonality. A mid-sized retailer cut stockouts by 18% after shifting to probabilistic forecasts that guided safety stock by service class. How are you quantifying uncertainty today? Share your approach and subscribe for practical forecasting tips.

From Forecast to Fulfillment: AI-Powered Demand Planning

AI blends POS data with weather, promotions, holidays, and social trends to detect early shifts in demand. One beverage distributor saw surges aligned to regional heatwaves and adjusted replenishment routes preemptively. Do you already ingest external signals? Tell us which sources moved the needle for you.

Real-Time Visibility and Predictive ETAs

By merging telematics, temperature loggers, and ELD data with traffic and port feeds, AI builds a living twin of your network. Teams see early warning signals, not just after-the-fact alerts. Have you tried digital twins? Share the most valuable data source you’ve added this year.

Real-Time Visibility and Predictive ETAs

Machine learning anticipates dwell time, customs delays, and weather disruptions, pushing proactive reroutes. One importer reduced detention fees by identifying at-risk containers 36 hours earlier. How do you prioritize exceptions today? Comment with your triage rules or subscribe to get our ETA checklist.

Lean, Smart, and Ready: Inventory Optimization

Instead of maximizing each node, AI optimizes the whole network—plants, hubs, and stores—cutting total inventory while holding service. A healthcare supplier moved slow-movers upstream and lifted fill rates for critical SKUs. Where do you suspect overstock is hiding? Share a blind spot you recently uncovered.

Supply chains are webs, not lists. Graph models map tier-2 and tier-3 dependencies, revealing hidden concentration risks. During a regional outage, one manufacturer safeguarded critical resin by switching to a previously underused supplier. How visible are your sub-tiers? Share your mapping approach.

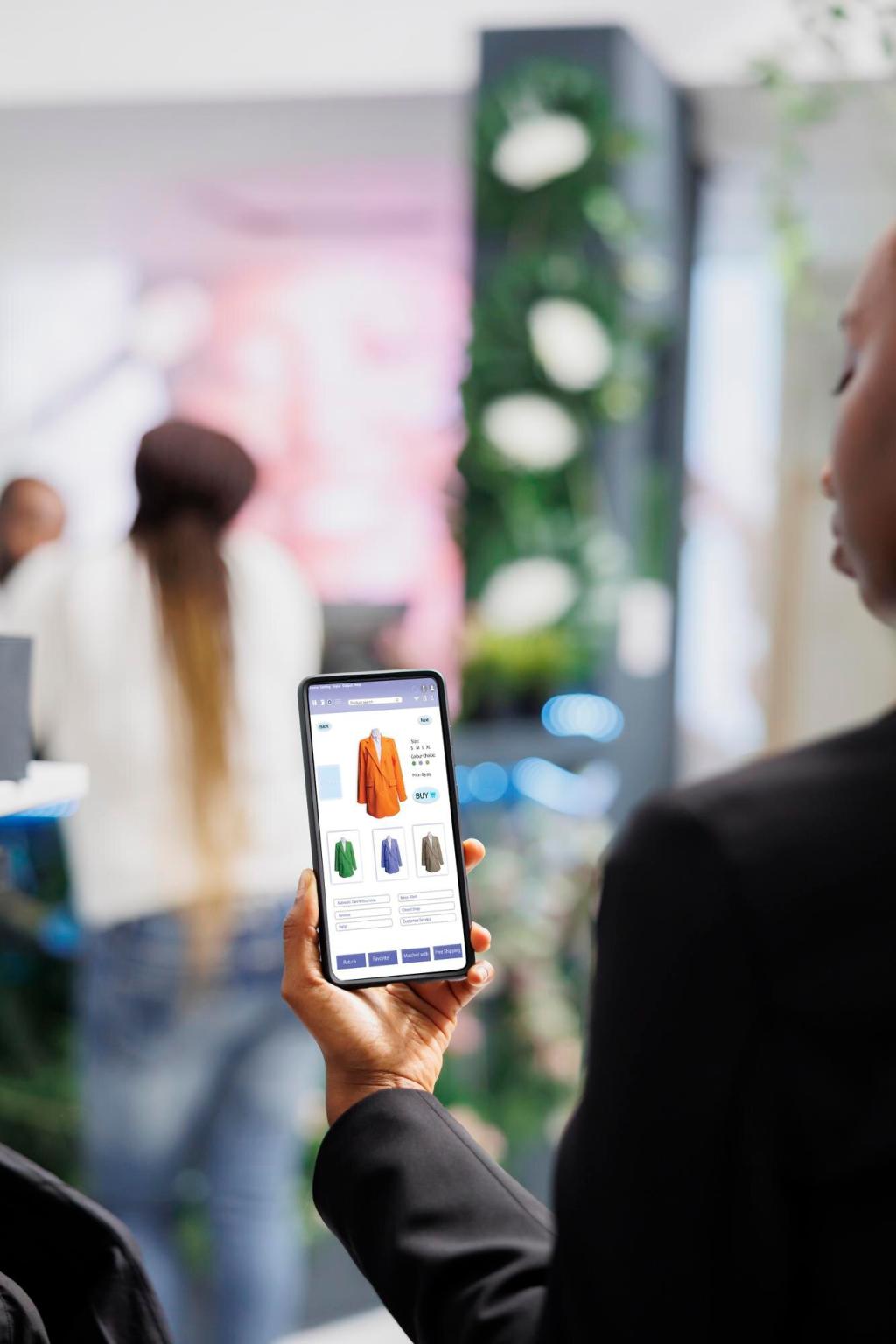

Warehouses that Think: Automation with People at the Center

Algorithms cluster picks, sequence waves by carrier cutoffs, and re-slot fast movers near pack stations. One site shortened average pick paths by 22% with AI-guided re-slotting. Which KPI would you tackle first—UPH, dock-to-stock, or OTIF? Share your vote and why.

Warehouses that Think: Automation with People at the Center

Cameras and computer vision verify labels, counts, and damages in motion, cutting audit time and returns. Pair with cycle counting to maintain trust in inventory. If you piloted vision systems, what surprised you most—accuracy, speed, or change management? Let us know.

Route and Mode Optimization for Lower Emissions

AI recommends consolidated routes, intermodal shifts, and backhaul matches to reduce empty miles and fuel burn. A consumer goods shipper matched regional returns with outbound loads to slash waste. Which sustainability win aligns with your cost goals? Tell us what you’re trying next.

Packaging and Dimensional Efficiency

Computer vision and optimization models right-size packaging, reducing air shipments and damage. The ripple effect lowers freight costs and carbon intensity. Have you measured dim weight improvements after packaging changes? Share your before-and-after results to inspire others.